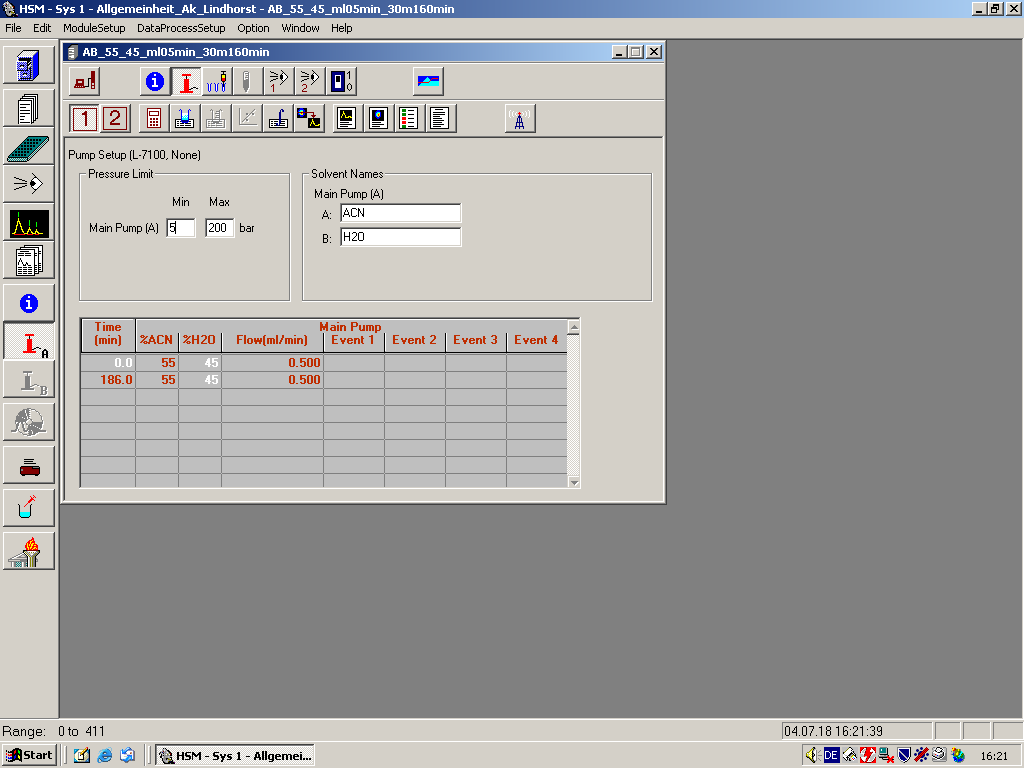

Pump Setup

The Pump Setup command is only available when a pump is selected from the Main Pump (A) drop-down list on the Method Configuration screen; otherwise, the command is disabled. Use this command if you want to review or modify pump-setup parameters.

Tool Bar Shortcut

| Setup Options | Description |

|---|---|

|

Pressure Limit Box |

Use to specify the minimum and maximum pressure limits. The minimum range is from 0 to 420 kgf/cm2 (this is equivalent to 0 to 5975 psi, 0 to 412 bar, or 0 to 41.2 MPa).The maximum range is from 1 to 420 kgf/cm2 (this is equivalent to 15 to 5975 psi, 1 to 412 bar, or 0.1 to 41.2 MPa). The pressure unit displayed here is the same as the pressure unit selected on the HSM Administration program. To change the pressure unit, you need to run the HSM Administration program.In the Low Gradient mode, enter pressure limits for Main Pump (A) and Acc Pump (B). In the High Gradient mode, the limit is set for All Pumps. |

|

Solvent Names Box |

Use to specify the names of the solvents associated with each pump (30 characters, maximum). The number of solvents is determined from the setup on the Method Configuration screen. Solvent names entered here are also automatically entered on the Method Information dialog. |

|

Solvent Time Table |

The Solvent Time Table defines the ratio of solvents with respect to time. The layout of the table is also dependent on the selections of the interface module, the gradient mode, and the number of pumps and solvents on the Method Configuration screen.

Time (min) --Use the Time column to enter the time (in minutes) at which the concentrations of solvents change, or when the flow rates change, or when the event signal is output. %... --The name headers are automatically assigned to each column with the first five characters of the solvent's name. In each %... column, enter the concentration of each solvent expressed as a percentage. Note: If only one solvent is used, the concentration is set to 100% automatically and is not editable. For more than one solvent, the last concentration (% value) is entered automatically by the HSM and sums the total to 100%. Flow (ml/min) --Use the Flow columns to enter the flow rate for the Main Pump (A) and the Acc Pump (B), or the total flow rate of all pumps, where applicable. Event --Use the Event columns to enter events during a run that will take place at specified times. With the D-6000 interface, two event columns, Event 1 and Event 2, are available only for the Main pump independent of gradient mode. With the D-7000 interface, four event columns, Event 1 through Event 4, are available for both main and accessory pumps (8 total) in Low Gradient mode. In the High Gradient mode, four event columns are available only for the Main pump.When you click in any row of the event column; a list box appears. Make a selection from the list.For the D-6000 Interface Module, the event signal selections include Off, On, Pulse options from eight ports, plus Stop and Buzzer. For the D-7000 Interface Module, the event signal options are Off, On, and Pulse. Off, on, or pulse represent relay event closures that are available on the back panel of the pumps. |

You can also leave a blank for some of these pump parameters in a row (except the very first row) if the row is used for changing other parameters. However, the HSM requires that at least one parameter field (besides Time) is not blank. Note that if you want to obtain the L-7100 pump pressure profile for the Module Performance Test (see Confidence Report) you need to set up at least two steps in the pump table with the time for the second step being 1.0 min or larger. The profile is available only to the time you specified in the last step. No pressure profile is available if the pump table has only one step.